Where Print and Apply Labeling Delivers the Biggest ROI

Where Print and Apply Labeling Delivers the Biggest ROI: Top Applications

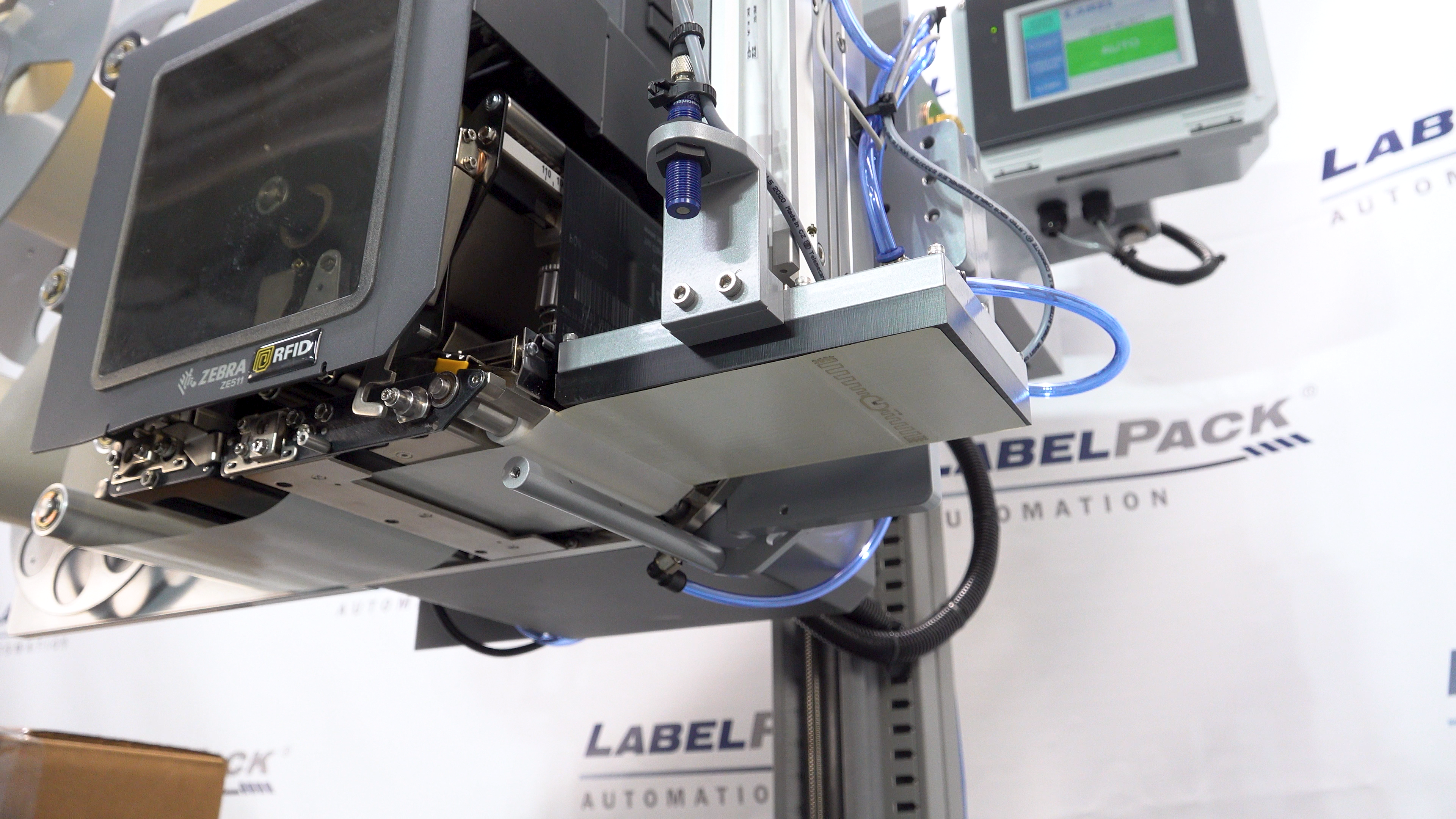

Print and apply labeling systems are essential for high-speed, high-accuracy operations where automation, efficiency, and traceability are critical. These systems are widely used in warehousing, logistics, manufacturing, and retail to ensure precise labeling, compliance, and seamless product movement.

In this blog, we’ll explore the top applications where print and apply labeling systems deliver the biggest impact, including cross-docking, distribution centers, e-commerce fulfillment, and more.

Cross-Docking Operations

Cross-docking requires quick, accurate labeling to ensure products are correctly sorted and shipped without long storage times. Automated print and apply systems generate and apply shipping labels in real-time, reducing errors and improving speed.

Key Benefits:

- Fast, real-time labeling to match shipment changes

- Reduces labor costs and human error

- Improves sorting and routing efficiency

Example:

A large retailer’s distribution center receives bulk shipments and redistributes them to multiple stores. A print and apply system automatically labels items for direct shipping, reducing turnaround time.

Distribution Centers & Warehouses

In high-volume distribution centers, labeling errors can cause delays, misrouted shipments, and costly chargebacks. Print and apply systems ensure that cartons, pallets, and totes are accurately labeled to meet retail and logistics compliance.

Key Benefits:- High-speed labeling for pallets, cases, and individual items

- Seamless integration with WMS, ERP, and conveyor systems

- Ensures compliance with major retailers (Amazon, Walmart, Target)

Example:

An automated warehouse receives mixed SKU pallets that must be broken down, relabeled, and shipped to different locations. A print and apply system ensures each item is relabeled correctly, reducing distribution errors.

E-Commerce Fulfillment & Shipping

E-commerce businesses process thousands of orders per day, requiring accurate, fast labeling for shipping, returns, and inventory tracking. A print and apply solution ensures barcodes, tracking labels, and return labels are correctly placed on packages with zero downtime.

Key Benefits:- Eliminates manual labeling errors in order fulfillment

- Speeds up shipping operations for faster delivery

- Enhances return processing with pre-printed return labels

Example:

A major e-commerce retailer automates its shipping line with print and apply systems that generate labels based on real-time orders, ensuring every package is labeled correctly before reaching the carrier.

Pallet Labeling & Inventory Management

Pallets require scannable, GS1-compliant labels for efficient warehouse tracking. Automated pallet labeling ensures that each pallet is accurately labeled with barcodes, lot numbers, and shipping details, reducing errors and speeding up inventory management.

Key Benefits:- Consistent, compliant labels for GS1 standards

- Reduces manual handling and label placement errors

- Integrates with warehouse scanners and tracking systems

Example:

A third-party logistics (3PL) provider applies automated pallet labels before loading trucks, ensuring quick scanning and tracking throughout the supply chain.

Retail Compliance Labeling

Retailers demand strict labeling compliance from suppliers. If a shipment arrives with incorrect or unreadable labels, companies face expensive fines and rejected shipments. Print and apply systems ensure each product, carton, and pallet meets retailer labeling requirements.

Key Benefits:- Ensures compliance with big-box retailers like Walmart & Target

- Reduces chargebacks for incorrect labeling

- Improves supply chain visibility with scannable barcodes

Example:

A clothing manufacturer applies UPC and RFID tags on boxes before shipping them to a national retailer, ensuring seamless stocking and checkout.

Cold Chain & Perishable Goods Labeling

Cold storage environments require specialized label materials that withstand moisture, condensation, and freezing temperatures. Print and apply systems handle automated labeling for perishable items like dairy, meat, seafood, and frozen foods.

Key Benefits:- Uses durable, cold-resistant label adhesives

- Ensures accurate expiration date tracking

- Improves traceability for FDA and USDA compliance

Example:

A frozen food distributor applies temperature-resistant barcode labels on cases before they enter refrigerated storage, ensuring traceability through the cold chain.

Automotive & Industrial Parts Labeling

Automotive and industrial parts require durable labels that withstand heat, oil, chemicals, and rough handling. Print and apply systems create rugged, permanent labels for manufacturing, logistics, and aftermarket tracking.

Key Benefits:- Ensures VIN, part number, and tracking labels meet industry standards

- Uses high-durability labels for harsh environments

- Reduces misidentified parts in assembly lines

Example:

An automotive assembly plant uses print and apply labeling for engine components, brake systems, and chassis parts, ensuring seamless tracking from production to installation.

Print and apply labeling systems are essential for industries where speed, accuracy, and automation are key. Whether it's cross-docking, warehousing, e-commerce, or cold storage, these systems ensure flawless labeling, improved efficiency, and compliance with industry standards.

Looking to automate your labeling process? Contact LabelPack Automation today to find the best print and apply solution for your application!