When to Replace Your Thermal Transfer Printer's Printhead

How to Tell When a Thermal Printhead Goes Bad

Thermal printers are widely used across various industries, from retail and logistics to healthcare and manufacturing. They offer fast, reliable, and cost-effective printing. However, like any piece of equipment, they require maintenance, and their components can wear out over time. One of the most critical parts of a thermal printer is the printhead. A failing printhead can lead to poor print quality, increased downtime, and wasted supplies. Here’s how to tell when your thermal printhead is going bad.

1. Faded or Incomplete Print Output

If your labels or receipts are printing with missing sections or faded text, this could be a sign of a worn-out printhead. Over time, the heating elements in the printhead can degrade, resulting in inconsistent heat distribution and poor print quality.

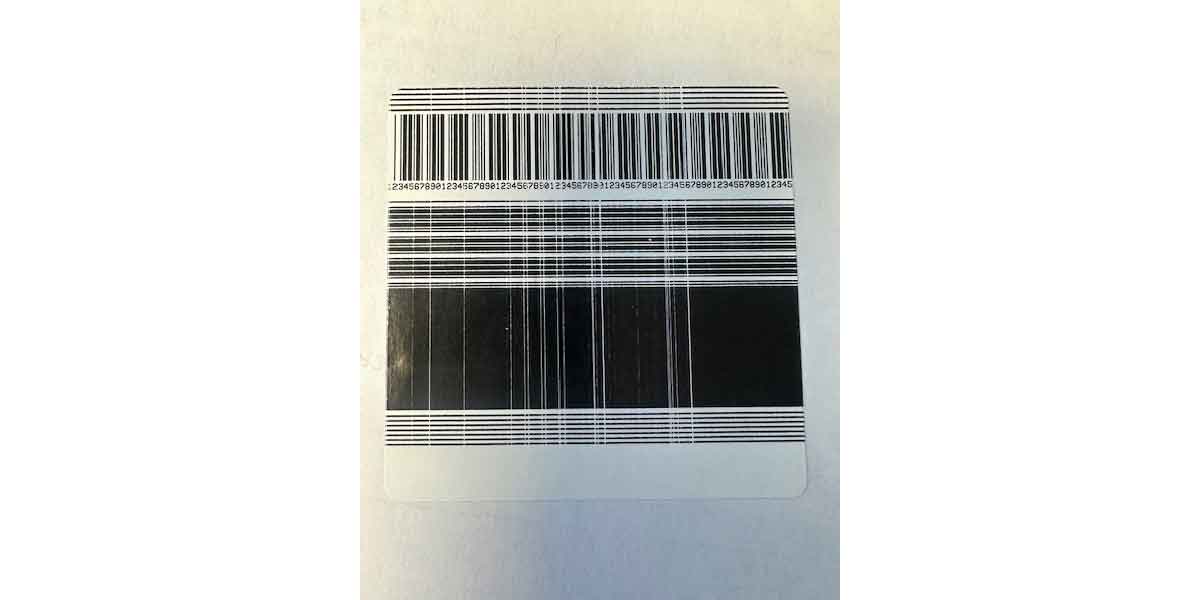

2. Streaks or Lines on the Print

One of the most common indicators of a failing thermal printhead is streaks or vertical lines appearing on the printed output. This happens when individual heating elements stop functioning, creating blank lines where the heat transfer does not occur properly.

3. Uneven Print Density

If parts of your print appear darker or lighter than others, this could be due to uneven pressure or heat distribution from a damaged printhead. This issue can also be caused by debris buildup, so cleaning the printhead first may help rule out simple maintenance problems.

4. Increased Printhead Temperature and Burnouts

As a printhead starts to wear out, it may require more power to achieve the same level of heat. This can lead to overheating, which may cause further damage and eventually lead to complete failure.

5. Frequent Ribbon Wrinkles (for Thermal Transfer Printers)

For thermal transfer printers, a damaged printhead can cause inconsistent contact with the ribbon, leading to wrinkles and uneven print quality. If you notice frequent ribbon wrinkling, inspect your printhead for signs of wear.

6. Physical Damage or Debris Build-up

A visual inspection can also help determine the health of your printhead. If you notice scratches, debris accumulation, or visible damage on the printhead surface, it could be the cause of poor print quality.

7. Error Messages on the Printer Display

Many modern thermal printers have built-in diagnostics that detect printhead issues. If you receive error messages related to printhead failure, it’s a strong indication that the component needs attention or replacement.

How to Extend the Life of Your Thermal Printhead

While thermal printheads will eventually wear out, you can take steps to extend their lifespan:

-

Regular Cleaning: Use manufacturer-recommended cleaning kits to remove dust, residue, and adhesive buildup.

-

Use High-Quality Supplies: Low-quality labels, ribbons, and adhesives can cause residue buildup and damage the printhead.

-

Adjust Print Settings Properly: Avoid using excessive heat settings unless necessary to prevent unnecessary strain on the printhead.

-

Handle with Care: Avoid touching the printhead with bare hands, as oils and dirt can degrade its performance.

When to Replace Your Thermal Printhead

If you’ve tried cleaning and adjusting settings but still experience poor print quality, it’s likely time to replace the printhead. Most thermal printheads have a lifespan measured in millions of inches of printed material, so refer to your manufacturer’s specifications for expected longevity.

By keeping an eye out for these warning signs and maintaining your printer properly, you can minimize downtime and ensure consistent print quality for your business operations. Need expert advice? We have trained and certified Zebra and Sato technicians on staff. Contact us for an on-site consultation or depot service.