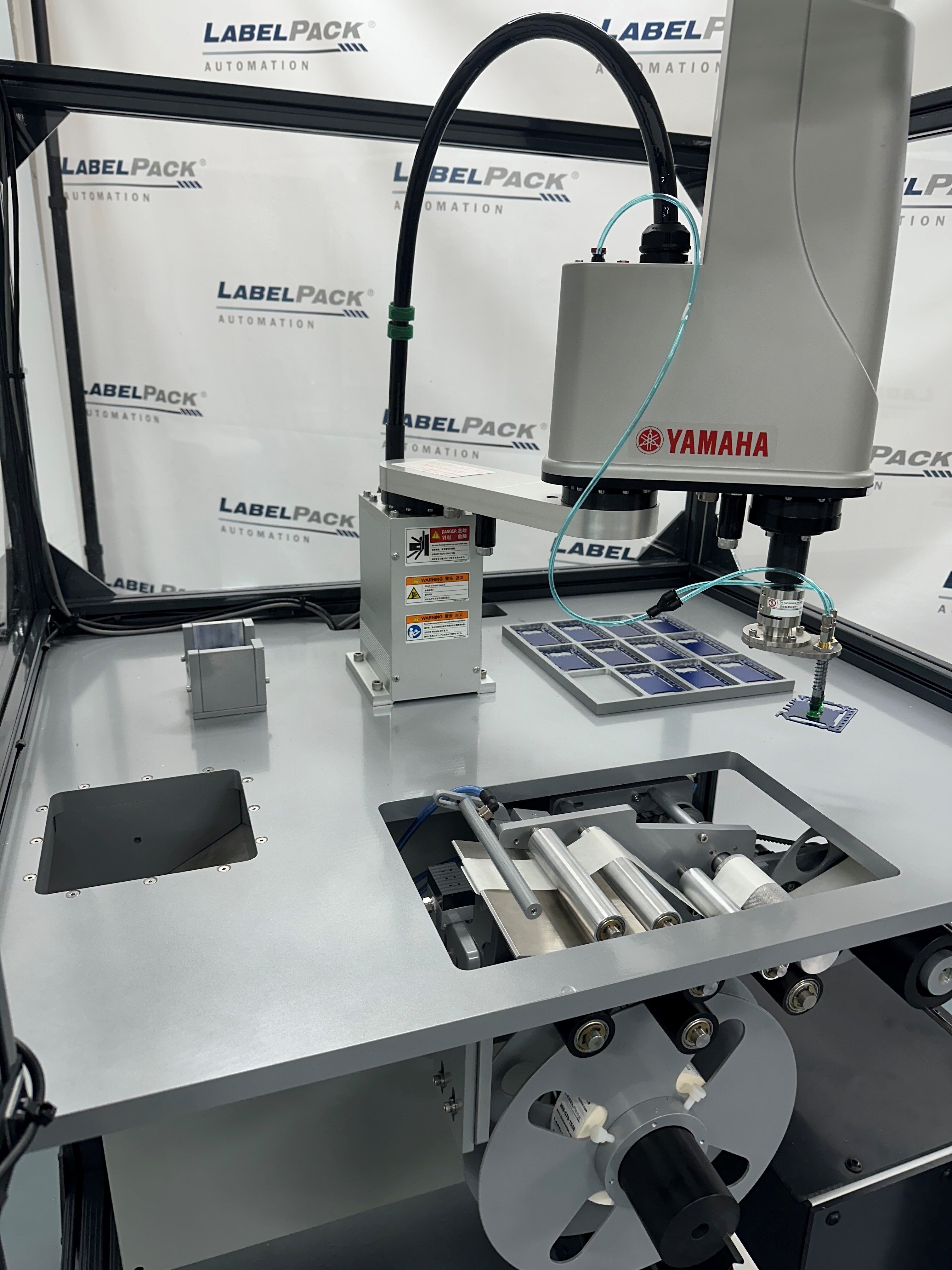

Automated Labeling and Handling System at Pack Expo International 2024

Introducing our Automated Labeling and Handling System, an advanced solution designed to demonstrate the future of automation at your fingertips. This demo showcases the full power of robotic precision, efficiency, and versatility—all in one system.

Key Features:

- Seamless Label Application: At the heart of the demo is our SCARA robot, moving products with pinpoint accuracy to the label applicator. Each label is applied with perfect precision, ensuring no misalignment or errors—something that can only be achieved through advanced motion control, real-time coordination, and meticulous engineering.

- Dynamic Multi-Tasking: What makes this system truly remarkable is its ability to handle multiple tasks. When the robot isn’t actively labeling, it’s shuffling parts through a complex grid. This shuffling isn’t just random; it involves highly complex programming to ensure the robot’s movements are smooth, efficient, and adaptable to different products. We’ve designed it to show that even in downtime, this system can contribute to overall productivity by preparing and organizing parts.

The Engineering Challenge:

Here’s the thing: what seems like smooth, effortless operation is the result of intricate, high-level engineering. Moving from one task (labeling) to another (shuffling parts) requires perfect coordination between the robot and the label applicator. Here’s what goes on under the hood:

- Precision Timing: The SCARA robot needs to know exactly when and how to move the product into the labeling position, as well as how to shuffle parts through the grid when it’s not in labeling mode. This requires perfect synchronization between the robot’s motion and the label applicator, all while maintaining speed and accuracy.

- Motion Complexity: Getting the robot to handle different tasks is no easy feat. It’s not just about moving in straight lines; the robot has to adjust for each product, ensuring it’s perfectly aligned for labeling. Meanwhile, shuffling through the grid involves constant, real-time calculations to avoid errors or collisions, all while maintaining smooth operation.

- Flexibility & Adaptability: This system is not limited to one task. It’s designed to be flexible, showcasing its ability to handle diverse products and perform multiple actions. This makes it ideal for industries where both precision labeling and dynamic part handling are required, demonstrating the versatility your production lines need.

Our demo is more than just a visual display—it’s a real-world solution to common production challenges:

Increased Efficiency: By automating both labeling and part handling, your operations can run continuously without downtime, maximizing productivity.

Error-Free Operation: Human error is eliminated. The robot handles repetitive tasks with consistent precision, meaning fewer mistakes and less waste.

Future-Proof Design: This system can easily be adapted to handle new tasks, new products, or more complex operations, making it a long-term solution as your production needs evolve.

This demo doesn’t just show what’s possible—it shows how we’ve already achieved what’s next. By integrating a SCARA robot with an automated label applicator and demonstrating complex part handling, we’re proving that automated systems can take on your most challenging tasks, save time, and increase throughput without sacrificing precision.

See it in action at our trade show booth, and discover how this powerful, multi-functional system can elevate your production line to the next level!