Platen Roller Purpose and Maintenance

How to Tell When a Thermal Platen Roller Goes Bad

Last month we talked about when to replace your printhead in your thermal transfer printer, but what about your platen roller? This essential yet often-overlooked wear part plays a major role in ensuring print quality and media handling. Platen rollers are frequently damaged over time, so knowing when to replace them is key to keeping your printer in top shape.

Just like any piece of equipment, thermal printers require regular TLC, and their components will wear out over time. The platen roller is the rubber roller located beneath the printhead. It applies pressure to your media—whether labels or tags—and ensures a consistent printing surface. If the platen roller becomes damaged or worn, it can significantly affect print quality and media feeding.

Here are the most common signs that your platen roller is going bad—and some tips to prevent premature failure:

1. Faded or Distorted Print

The most common sign of a bad platen roller is faded, distorted, or inconsistent print quality. This may indicate:

-

A contaminant (adhesive, dust, oil) on the roller.

-

A worn or damaged surface that’s no longer providing even pressure.

Before replacing the roller, try cleaning it—if the issue persists, it may be time for a new one.

2. How to Clean a Platen Roller

Contaminants like adhesives, dust, and oils can build up and interfere with performance. To clean the platen roller:

-

Use a lint-free swab or cloth.

-

Dampen with 99.7% isopropyl alcohol.

-

Gently wipe the roller, rotating it to clean the entire surface.

Always clean the roller promptly if a label wraps around it or gets stuck.

3. Check for Uneven Wear

f you frequently run the same label size; your platen roller may develop grooves or indentations in specific areas. Inspect it for:

-

Visible wear lines.

-

Flat spots or uneven surfaces.

The roller should be uniform across its entire width. If not, it’s time to replace it.

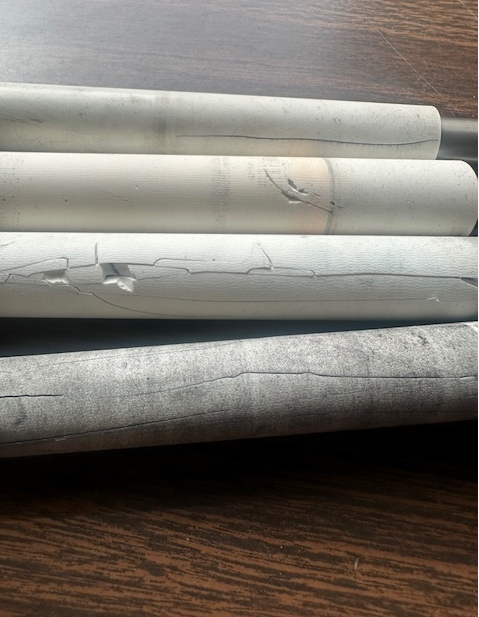

4. Check for Cuts or Damage

Occasionally, platen rollers are accidentally damaged during label removal. We’ve seen cases where users tried to remove jammed labels with sharp tools like pocketknives, causing gouges or cuts in the roller. Any physical damage like this will lead to poor print quality and requires immediate replacement.

How to Extend the Life of Your Thermal Platen Roller

While platen rollers will eventually wear out, you can take steps to extend their lifespan:

-

Regular Cleaning: Follow a routine maintenance schedule using manufacturer-approved cleaning supplies.

-

Use High-Quality Materials: Cheap labels, ribbons, and adhesives can leave residue and accelerate roller wear. Always use quality supplies that are compatible with your printer. If we’re not currently your supplier for labels, ribbons, or printer parts, we’d love the opportunity to earn your business—contact us today for a quote or consultation.

By keeping an eye out for these warning signs and maintaining your printer properly, you can minimize downtime and ensure consistent print quality for your business operations. Need expert advice? We have trained and certified Zebra and Sato technicians on staff. Contact us for an on-site consultation or depot service.